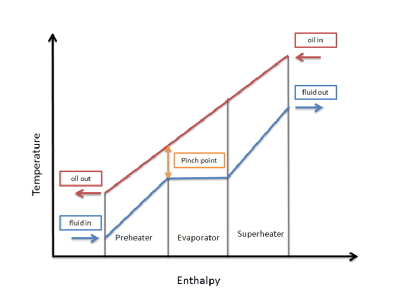

Pinch Point Analysis is a systematic process design methodology consisting of a number of concepts and techniques that ensure an optimal use of energy. The Pinch is characterized by a minimum temperature difference between hot and cold streams and designates the location where the heat recovery is the most constraint.

The fundamental computational tool is the Problem Table algorithm. This tool allows the identifications of the Pinch, as well as of targets for hot and cold utilities.

The net heat flow across Pinch is zero. Consequently, the system can be split into two stand-alone subsystems, above and below the Pinch. Above the Pinch there is need only for hot utility, while below the Pinch only cold utility is necessary. For given ΔTmin the hot and cold utility consumption identified so far becomes Minimum Energy Requirements (MER). No design can achieve MER if there is a cross-pinch heat transfer.

The partition of the original problem in subsystems may introduce redundancy in the number of heat exchangers. When the capital cost is high, it might be necessary to remove the Pinch constraint in order to reduce the number of units. The operation will be paid by supplementary energetic consumption, which has to be optimized against the reduction in capital costs.

The result is that heat recovery problem becomes an optimization of both energy and capital costs, constraint by a minimum temperature approach in designing the heat exchangers. Stream selection and data extraction are essential in Pinch Analysis for effective heat integration.

The key computational assumption in Pinch Point Analysis is constant CP on the interval where the streams are matched. If not, stream segmentation is necessary

The counter-current heat flow of the streams selected for integration may be represented by means of Composite Curves (CC). Another diagram, Grand Composite Curve (GCC) allows the visualization of the excess heat between hot and cold streams against temperature intervals. This feature helps the selection and placement of utilities, as well as the identification of the potential process/process matches.

The synthesis of a Heat Exchanger Network consists of three main activities:

- Set a reference basis for energy integration, namely:

-Minimum Energy Requirements (MER)

-Utility selection and their placement

-Number of units and heat exchange area

-Cost of energy and hardware at MER

- Synthesis of heat exchanger network (HEN) for minimum energy requirements and maximum heat recovery. Determine matches in subsystems and generate alternatives.

- Network optimization. Reduce redundant elements, as small heat exchangers, or small split streams. Find the trade-off between utility consumption, heat exchange area and number of units. Consider constraints

The improvement of design can be realized by Appropriate Placement and Plus/Minus principle. Appropriate Placement defines the optimal location of individual units against the Pinch. It applies to heat engines, heat pumps, distillation columns, evaporators, furnaces, and to any other unit operation that can be represented in terms of heat sources and sinks.

The Plus/Minus principle helps to detect major flow sheet modifications that can improve significantly the energy recovery. Navigating between Appropriate Placement, Plus/Minus Principle and Targeting allows the designer to formulate near-optimum targets for the heat exchanger network, without ever sizing heat exchangers.

Pinch Point principle has been extended to operations involving mass exchange. Saving water can be treated systematically by Water Pinch methodology. Similarly, Hydrogen Pinch can efficiently handle the inventory of hydrogen in refineries. Other applications of industrial interest have been developed in the field of waste and emissions minimization. The systematic methods in handling the integration of mass-exchange operations are still in development. In this area the methods based on optimization techniques are very promising.

Recent Comments